Industry news|2022-04-12| admin

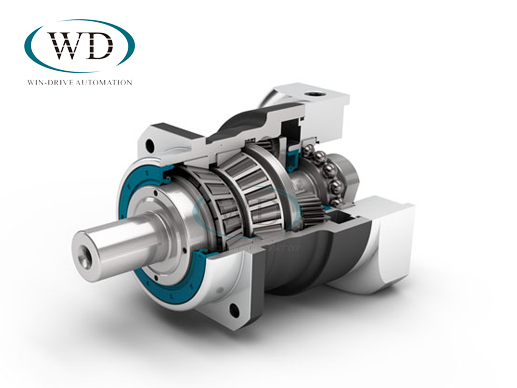

The characteristic of the servo gearbox is that it has planetary gears, which can revolve around the axis and also rotate. The gearbox has the advantages of small size and large transmission ratio, and is widely used in automation and other industries. So what problems should be paid attention to in the installation of servo gearbox, let's take a look.

Generally speaking, the weight of a servo gearbox gear is closely related to its material and heat treatment hardness. For example, under the same power, the weight of the carburized and quenched gear will be about 1/3 of that of the quenched and tempered gear. Therefore, according to the structural characteristics of the planetary gear gearbox and the load characteristics of the gears, hardened gears should be widely used. There are many heat treatment methods to obtain hardened gears, such as surface quenching, integral quenching, carburizing quenching, nitriding, etc. , should be selected according to the characteristics of the planetary gear gearbox.

Please pay attention to the following details during installation

When installing the servo gearbox, attention should be paid to the alignment of the transmission center axis, and the error should not be greater than the compensation amount of the coupling used. It can prolong the service life and obtain the ideal transmission efficiency. When installing the transmission parts on the output shaft, it is not allowed to hit with a hammer. Usually the transmission part is pressed in by means of the assembly fixture and the inner thread of the shaft end with bolts, otherwise the internal parts of the servo gearbox may be damaged. It is best not to use rigid fixed couplings, because improper installation of such couplings will cause unnecessary external loads, resulting in early bearing damage, and even breakage of the output shaft in severe cases.

The servo gearbox should be firmly installed on a stable foundation or base, the oil in the oil discharge tank should be drained, and the cooling air should circulate smoothly. Unreliable foundations can cause vibration and noise during operation and damage bearings and gears. When the drive coupling has protrusions or is driven by gears and sprockets, consideration should be given to installing guards. When the output bearing is subjected to a large radial load, it should be reinforced.

Depending on the designated installation, the oil level, vent plug and drain plug are easily accessible by staff. After installation, the accuracy of the installation position of each fastener and the reliability of pressing should be comprehensively checked in sequence. After installation, the fasteners should be able to rotate flexibly. The gearbox is splash lubricated by an oil sump. Before operation, the user needs to remove the vent plug and replace the vent plug. According to different installation positions, open the oil level plug screw, check the height of the oil level line, add oil from the oil level plug until the lubricating oil overflows from the oil level plug screw hole, screw on the oil level plug, and after confirming that it is correct, you can empty it. Load test run, time not less than 2 hours. Smooth operation, no shock, vibration, noise and oil leakage. If any abnormality is found, it should be eliminated in time.

After a period of time, the oil level should be checked again to prevent possible leakage of the casing. If the ambient temperature is too high or too low, the brand of lubricating oil can be changed.

Precautions for installation of precision servo planetary gearbox:

1. Before installation, wipe the anti-rust oil on the motor input shaft, positioning boss and connecting parts of the servo planetary gearbox with gasoline or zinc-sodium water.

2. During installation, knocking is prohibited to prevent excessive axial force or radial force from damaging the bearing or gear.

3. Before the motor is connected to the gearbox, the keyway of the motor shaft should be perpendicular to the fastening bolt.

The above is the relevant knowledge about the installation precautions of the servo gearbox, I hope it can help you.